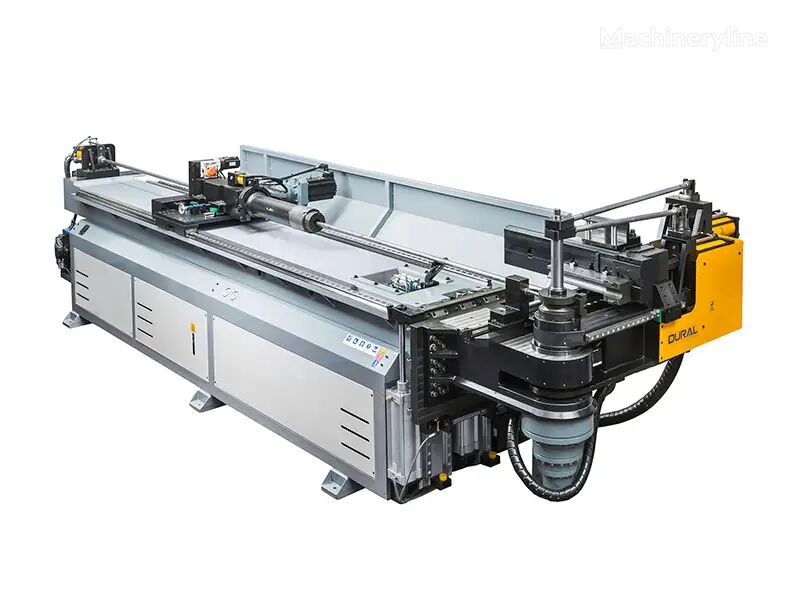

New Dural Griffin pipe bending machine

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

Turkey

Turkey

The machines also have intuitive and well-designed interfaces, allowing for maximum control while still keeping the process simple. Our CNC technology allows you to produce tube geometries, no matter how complex or run them for high-volume production runs with pinpoint precision in every last detail. They can switch between multiple functionalities, allowing the business to roll out any type of project without wasting time and resources with programmable flexibility.

CNC tube bending machines manufactured by Dural Makine is significantly useful in industries such as automotive, where accuracy and uniformity are crucial. Featuring world-class components and groundbreaking software, our machines don not only enhance the industrial yield but also reduce raw material wastage providing the dual benefit of cost-effectivity and eco-friendliness.

Let Duralbend take you into the era of tube bending with your CNC solutions. Allow us to bring your production standards standard up and refine every project into excellence.

Flexible bending and working capacity with CNC control system.

The capacity to adjust molds in 3 different radius scales for min 3 stack machines

Ability to automatically convert 3D technical drawings to bending program

Multivariable roll bending system for min 3 stack machines

Ability to work with or without a mandrel

Automatic oil cooling system

With linear guideway systems minimize the system gaps in moving parts

Program changing feature while in the bending process

ETU bending simulation program, for bending process, helps to make 3d tube bending arising from the coordinates, with excellent results.

With DcOnTool tool, you can convert X, Y, Z coordinates to bending program (Y,B,C)

Can review the last error messages with Dlog

Its user-friendly, easy, knowledgeable and quick-to-learn design allows you to start the project quickly.

Easy to use with 17 inch controller.

The vibration-free structure shall help your work.

Unlimited program saving and changing

Turkish – English and French language

10 years sending spare parts