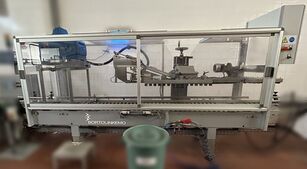

Apsol ACS30HM carton sealer

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

Italy

Italy

Used Case Sealer APSOL 3500 bph

The Used Case Sealer APSOL 3500 bph performs automatic sealing of American-type cartons using hot-melt adhesive. Specifically designed for high-output bottling lines, this automatic case sealer provides reliable solutions that ensure tight closure, consistent efficiency, and enhanced operational safety. With a rated speed of 3500 bottles per hour, it meets industrial demands. Moreover, the machine accommodates multiple container formats and integrates seamlessly with standard configurations in the beverage industry.

Technical Specifications of the ACS30HM Model

APSOL manufactured this machine in 2007, and it currently operates in production. The structure, although compact, offers robust mechanical performance. Additionally, the integrated DELTA-type PLC system controls the sealing cycle, thermal adhesive regulation, and overall workflow with precision. As a result, operators benefit from accurate process control. The Used Case Sealer APSOL 3500 bph runs on a 400 Volt three-phase power supply, consumes 5 kW, and operates at a frequency of 50 Hz. Therefore, it remains fully compatible with European industrial standards.

Supported Formats and Production Flexibility

In terms of versatility, the Used Case Sealer APSOL 3500 bph processes various carton formats containing 500 ml, 750 ml, and 1000 ml bottles in 4×3 and 3×2 configurations. Furthermore, it offers high production flexibility and quickly adapts to different layout requirements. Operators can perform format changeovers rapidly; consequently, they minimize downtime and optimize line efficiency. In addition, the design facilitates routine adjustments without requiring extensive reconfiguration.

Hot-Melt Adhesive Sealing System

The machine uses a hot-melt adhesive applicator to ensure secure sealing. Unlike mechanical closure systems, this method provides strong adhesion that withstands both mechanical and thermal stress during transport and handling. Notably, the integrated sensors maintain a consistent operating temperature, while the adhesive distribution system guarantees even application. As such, the Used Case Sealer APSOL 3500 bph offers high-quality and repeatable sealing performance. Simultaneously, it reduces the need for rework and rejects.

Safety Systems, Manuals, and Regulatory Compliance

The Used Case Sealer APSOL 3500 bph includes safety systems that protect operators during operation and maintenance. In particular, safety barriers, emergency stop buttons, and certified electronic controls ensure compliance with European workplace safety regulations. Additionally, APSOL supplies the machine with comprehensive manuals covering installation, maintenance, and troubleshooting. Consequently, technicians can integrate and operate the machine efficiently from day one. Beyond basic documentation, the manuals also contain detailed schematics and recommended service intervals.

Operational Summary

Thanks to its structural strength, processing speed, and format adaptability, the Used Case Sealer APSOL 3500 bph serves as a reliable solution for end-of-line automation in bottling plants. Moreover, the inclusion of an advanced PLC, combined with its compatibility with hot-melt adhesive systems, enhances overall performance. In conclusion, this machine provides dependable sealing, minimal downtime, and seamless integration—making it an ideal choice for high-performance industrial environments.

Speed: 3500 BPH

Products: Oil

Containers: Glass

Formats: 0.50 L, 0.75 L, 1.0 L

Measurements: Width: 1100mmLength: 3200mm Height: 2150 mm

Electrical data: V: 400Vkw: 5kwhz: 50hz

Safety features: Yes

Manuals: Yes

Closure: Hot Melt